24% off

EU Ship No Tax 2025 Xhorse Dolphin XP-008 XP008 Manual Key Cutting Machine for Special Bit, Double Bit Keys with Built-in Battery

Art.-Nr. SL485

Auf Lager.

Geschichte 224 verkauft.

Letzter Preis: €699.00Kaufe jetzt: €531.00

24% off

Buy Key Tool Plus Advanced Version,Get Free One Year Unlimited BGA and ID48 Token

Need Better Price, Please Contact:

Email: sales@XhorseShop.de

Whatsapp:+86-19947586579

Need Better Price, Please Contact:

Email: sales@XhorseShop.de

Whatsapp:+86-19947586579

Versand:

Kostenloser Versand

Express Shipping Service

Estimated delivery time: 3-5 Days.See details »

Gewicht:

12.5KG

Paket:

43.5cm*37cm*31.5cm

( Inch: 17.13*14.57*12.4 )

Kehrt zurück:

Return for refund within 30 days,buyer pays return shipping. Read details »

Produktbeschreibung

XHORSE DOLPHIN XP-008 MINI mechanical key cutting machine has an all-aluminum body, so its good quality is fully guaranteed. With a 0~45°rotation bench, which is a revolution in design, XP-008 can perfectly cut keys with different titled angles.

Xhorse Dolphin XP-008 XP008 Manual Key Cutting Machine for Special Bit, Double Bit Keys with Built-in BatteryHighlights:

1. Designed for Duplicating Bit/ Pump and Safe Deposit Box Keys.

2. Ergonomic Design with Superior Mechanical Structure

3. All-Purpose Clamps and Ultra-High Precision Processing

4. All-Aluminum Body-Reliable and Durable

5. Finest Details-Precision Manufacturing

6. Micro-Adjustable Knob for Higher Precision Cutting

7. Advanced Rotary Clamp Enable More Possibilities

8. Top Pick for Cutting Bit/ Pump and Safe Deposit Box Keys

9. Wide Clamp Space Fit for Keys of Different Length

Notice:

Engineer will Test the Key Cutting Machines to Ensure There is No Problem Before the Delivery.

Testing the key blads may generated tiny iron filings, that's not means is a used machine or a second hand machine.

Features

1. Designed to Meet Diverse Demands

To meet the needs of a wide range of users, DOLPHIN XP-008 is specially designed to duplicate various bit/pump and safe deposit box keys

2. Exceptional Design

Ergonomic design brings users an extraordinary working experience.

DOLPHIN XP-008 comes with an LED light, helping users work in different scenes with ease.

Users can complete the lateral cutting feed by simply turning the handwheel which can be entirely concealed inside after duplication.

3. Efficient Cutting Guaranteed

The spindle speed reaching 1050rpm guarantees high efficiency in cutting. More importantly, it helps minimize the wear and tear of the cutter and ensures high-quality cutting results.

4. Innovative Micro-adjustment Base

The all-direction micro-adjustment base consisting of a key cutting guide and micro-adjustment knob is innovatively developed, making it possible to achieve ultra-high precision duplicating.

5. Flexible Clamps

The machine features a wide clamp space reaching 115mm, providing a more flexible experience to clamp different keys with no limits to the stem length.

XP-008 also offers a wide rotation range so the rotation bench can rotate 0〜45° when turning the handle. This makes sure that keys with different titled angles can be perfectly cut.

Dolphin XP008 vs Condor XC009

| Key Cutting Machine | Condor XC-009 | Dolphin XP-008 |

| Function | ||

| Manipulation | Manual Cutting | Manual Cutting |

| Cutting Tool | Cutting Plate | Cutting Plate |

| Cutting Key | Single/Double-Sided Key |

Bit/Double Bit Key |

| Multi-Function Clamp | 4-Side Clamp | 3-Side Clamp |

| Built-in Battery | √ | √ |

| Parameter | ||

| Power | 110W | 145W |

| Spindle Speed | 900rpm | 1050rpm |

| Net Weight | 10.8kg | 10.8kg |

| Gross Weight | 14.0kg | 12.5kg |

| Machine Dimensions | 285*175*200mm | 305*185*200mm |

| Package Dimensions | 420*310*300mm | 435*370*315mm |

Specification

Input Frequency: 47-63Hz

Spindle Speed: 1050rpm

Travel of Table: 46mm

Clamp Rotation Angle: 0-45°

Machine Dimensions: 305x185x200mm

Package Dimensions: 435x370x315mm

Power: 145W

Input Voltage: 12V/DC

Motor Torque: 1.32Nm

Package List:

1set x Xhorse Dolphin XP-008 XP008

Contact us:

Email: sales@XhorseShop.de

Whatsapp:+86-19947586579

+86-13429866263

Wechat: +86-13429866263

Technical Support

Step 1. Install Calibration Plate*First, make sure machine's power is off.

Hold calibration rod and loosen the clamp, then take out calibration rod.

Stick it into spindle pinhole

Loosen lock screw using a wrench.

Remove the cutter (cutting plate).

Install calibration plate, same as before.

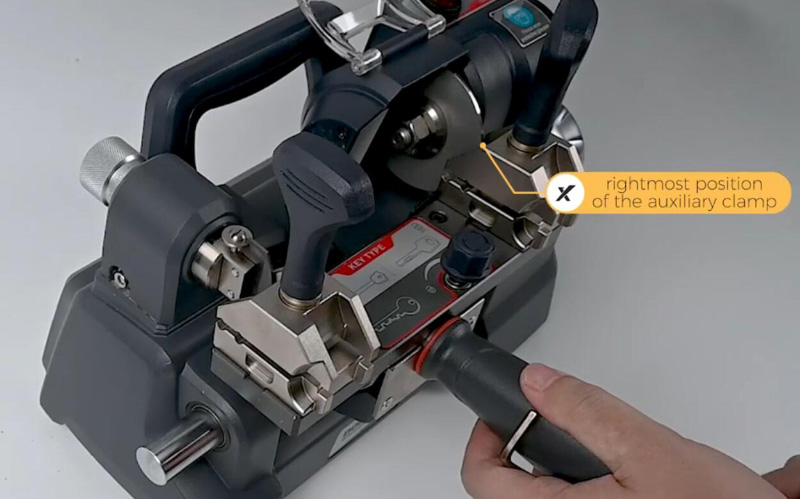

Step 2. Lateral Adjustment of Micro-adjust Base

*First, make sure the main and the auxiliary clamps stay Side A.

Rotate handle until calibration plate touches right part of auxiliary clamp.

Slightly loosen fixing screw of sliding base.

Adjust left adjusting screw using an Allen wrench until cutting guide touches right part of main clamp.

Tighten fixing screw of sliding base.

Step 3. Vertical Adjustment of Micro-adjust Base

Stick calibration rod into clamps and tighten it.

Adjust knob of micro-adjust base so that calibration rod can touch left cutting guide and right calibration plate in the meantime.

Step 4. Height Adjustment of Micro-adjust Base

*Generally, the procedure is already complete by factory.

Rotate handle, and make sure calibration rod keeps touching left cutting guide and right calibration plate in the meantime.

Done!